¿No encuentras lo que buscas?

Crea un anuncio de búsquedaIndustry digitization accelerates in pandemic

Despite the fact that the concept of Industry 4.0 was generated more than a decade ago, this last year it has had a rebound in its materialization. The reason, we all know: the global pandemic. The consulting firm KPMG projects that for this year the industry 4.0 market will amount to 3.4 billion euros.

This new conjuncture has brought consequences in all the industries that in some cases took a boom and in others have lagged, however, both currents look towards digitization as an inevitable process.

Industry 4.0 seeks digital transformation in infrastructure and in processes that have an impact on transportation, mining, agriculture, construction, among other economic areas. Alejandro Nacarino, ER-Soft Sales Manager, commented in a recent interview that the change introduced by Industry 4.0 is not in production but in the innovation of the process and the business model.

Let's see what this accelerated digitization is all about in this decade transition.

Transport 4.0 and Logistics 4.0: Trends that are imposed

One of the branches that has the greatest weight in the transport industry is Logistics 4.0, which seeks to accelerate and consolidate the processes that are linked to connectivity and communication and that are influenced by the Internet of Things (IoT), Big data. , ecommerce, blockchain, Artificial Intelligence (AI) and technologies for autonomous transport. A whole host of technological mechanisms that seek the speed and efficiency required.

One of the branches that has the greatest weight in the transport industry is Logistics 4.0, which seeks to accelerate and consolidate the processes that are linked to connectivity and communication and that are influenced by the Internet of Things (IoT), Big data. , ecommerce, blockchain, Artificial Intelligence (AI) and technologies for autonomous transport. A whole host of technological mechanisms that seek the speed and efficiency required.

In the United States alone, the trucking industry and the logistics market is a 1.3 trillion dollar business taking into account that the transportation sector consists of several branches such as air, land, maritime, airlines, logistics and its infrastructure where all these technologies have a place and are necessary.

In the case of the adoption of Blockchain technology, it has allowed the recording of transactions, asset tracking, monitoring of the performance of operators and suppliers, execution of smart contracts, security in the supply chain, etc.

Not to mention smart IoT-enabled trucks with real-time video, mapping, and driving data that not only make it easy to monitor brakes, fuel, or speed; but to track shipments and offer greater security against accidents or dangers on the road.

In addition, the Internet of Things is transforming the transportation industry by collecting data related to the automation of mobility. Communication is improved and data distribution with trains, trucks, ships and airplanes is optimized.

For only placing a case in the maritime industry, last year an agreement was signed between the Norwegian DNV and ABB taking into account that 80% of the operations are carried out by shipping companies and that by 2050 that amount will be multiplied by four. Said agreement proposes to develop the smart ports of the near future to control the management systems, entrances and exits in even mechanisms to identify the trucks that operate in the port area. Examples of this are the port of Barcelona, Spain, where entries and exits are already managed automatically, the port of Callao, the maritime single window in Panama, the Port Community System (PCS) of the African port of Cotonou and the exemplary case of the intelligent port of Antwerp, in Belgium.

In this regard, the International Association of Ports and Bays (IAPH) together with the World Bank published the report "Accelerating digitization: critical actions to strengthen the resilience of the maritime logistics chain" which among other data showed that, as of November 2020 Only 49 of the 174 member states of the International Maritime Organization (IMO) have functional port community systems. There is still work to be done in terms of automation and digitization of the industry.

AI is also doing its part in transportation by managing traffic and increasing spassenger safety. The types of AI used in transport go through Knowledge-based Systems (KBS), Neural Networks (NN), Fuzzy Systems (FS), Genetic Algorithms (GA) and Agent-based Methods (ABM) among others. .

Another trend of industry 4.0 in transport is Big Data that has revolutionized the field of logistics with predictive analytics to avoid interruptions in the transport system and its maintenance.

Big Data logistics optimizes routing with data controlled by physical-intelligent sensors, factory functions, transparency to the entire supply chain, real-time analysis and traffic of meteorological data from sensors and forecasting systems among other applications.

And we cannot leave out the drones and autonomous trucks that are already impacting road safety and on-time delivery, among other benefits to this industry that gives mobility to all other industries.

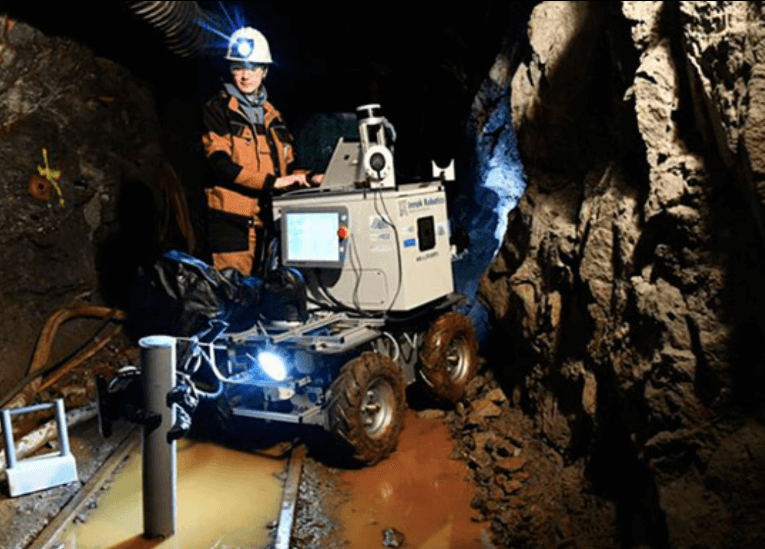

Mining 4.0

In this new context, the possibility of operating the mining industry remotely becomes more relevant, understanding that all the trends in automation and digitization of mining 4.0 have generated that the “smart mining market” has been valued at 6.8 trillion dollars by 2019 and reach an estimated price of 20.31 trillion by 2025.

In this new context, the possibility of operating the mining industry remotely becomes more relevant, understanding that all the trends in automation and digitization of mining 4.0 have generated that the “smart mining market” has been valued at 6.8 trillion dollars by 2019 and reach an estimated price of 20.31 trillion by 2025.

In this regard , 3D modeling techniques, wearables, business intelligence, added to those already mentioned, such as Artificial Intelligence, drones and IoT, achieve unique applications in the mining industry.

For example, experts maintain that 3D modeling will have a strong development due to the possibility of precision to recreate underground spaces, which implies a saving of resources and greater safety for its workers. Likewise, the AI and the mobility capacity of the drones will contribute to the efficiency of the mining site .

Some automation challenges in underground mining have already been solved by applying real-time wireless data transmission systems. WiFi systems, especially LTE and 4G, have been installed in the mines to guarantee the traceability of all the information. The use of electric vehicles has also been another solution within the mines.

Additionally, the Internet of Things has been another of the advances that has gained importance, especially with regard to the sensorization of the elements that participate in the mining operation. It is estimated that this technology will become widespread in the coming years in industries of all kinds, which will represent 2 trillion dollars for the world market by 2023.

In this sense, Chile, a leading country in copper mining, established a road map, promoted by the Mining Council and other organizations, for the digitization of this industry and towards a 4.0 mining that seeks to enable digital transformation for the next 15 years . More technological changes are coming in this area.

For that smart industry

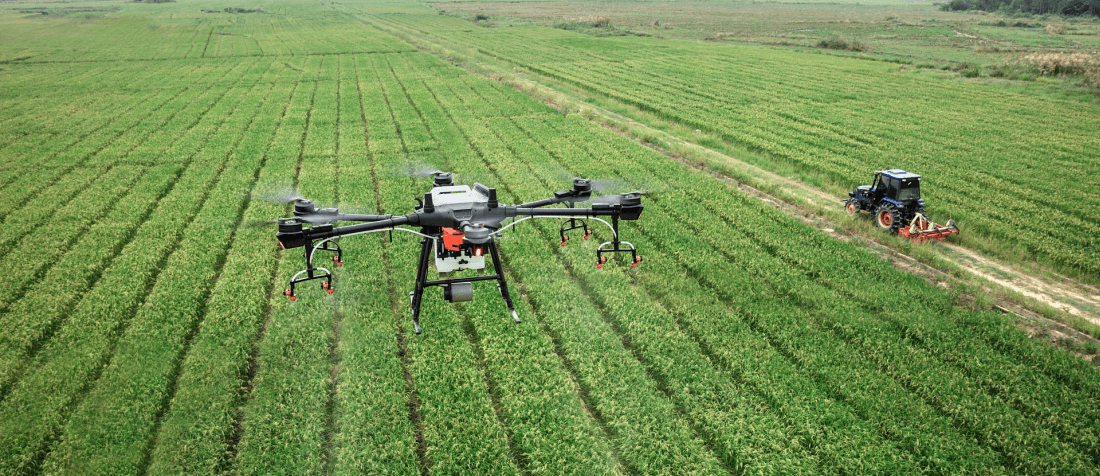

In the case of Agroindustry 4.0 and Construction 4.0, the trends of advances in the use of all the tools that technology provides have also been applied.

In the case of Agroindustry 4.0 and Construction 4.0, the trends of advances in the use of all the tools that technology provides have also been applied.

Various studies estimate that by 2024 around 600,000 robots dedicated to the agrotechnology industry will be produced per year, while in 2016 there were only 32,000.

In recent years, international agreements have been made between companies dedicated to technology and agriculture (Intel, Cargil, Keenan and Cainthus are some of those involved) and startups dedicated to what is called Agtech or digital technology applied to agriculture have been born. .

The startup Milar developed the Argentine app EcoSniper as a local selective spraying system that allows specific herbicides to be treated within a batch to save product and minimize damage to the environment.

e = "font-weight: 400;"> Likewise, in Chile remote sensors were implemented around the blueberry production areas to monitor soil conditions and optimize the irrigation process using the necessary water and saving 70% of the volume of liquid used.

Also, the development of 5G technology has leveraged the use of AI and IoT in rural areas. Just to give an additional piece of information, the Internet of Things market will be valued in 2020 at approximately 3.2 billion euros and agribusiness will be one of the beneficiaries.

Finally, construction is not far behind, since AI has been experienced through Machine Learning where, with the programming of algorithms, the computer recognizes and learns complex patterns as data is supplied to it.

Likewise, Building Information Modeling (BIM) is applied as a collaborative methodology to create and manage construction projects with the aim of centralizing the information in a digital information model that unites the virtual construction and the data that those involved in the project provide. .

This is just a fourth revolution that will offer endless opportunities to the industry. There is the data and the layout. Let's see who gets into all the possibilities that technology offers and begins to consolidate their projects.

related links

- White 1791, 21st Floor

- Valparaíso, Chile

- Monday-Friday 9 am to 6 pm

- support@mercadoequipos.cl

- +56 2 3210 4870

Copyright © 2018 Servicios Mercado Equipos Ltda.